What is The Procedure For Selecting a Liquid Filling Machine?

Time:Jan 2, 2024 Hits:Introduction

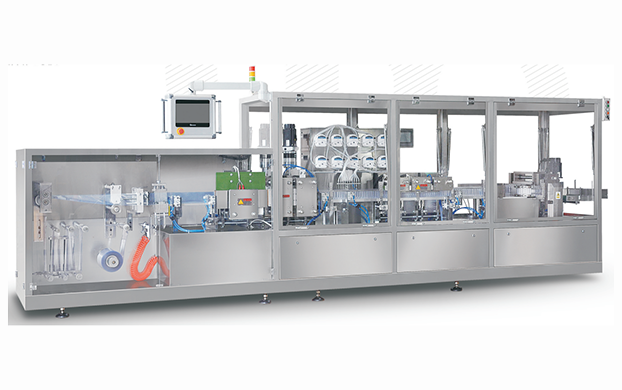

Choosing the appropriate liquid filling machine is a crucial choice for any company operating in the packaging sector. A great deal of variables need to be carefully considered along the process so as to achieve savings, accuracy, and speed. We will go over the important factors to take into account when selecting the best liquid filling machine for your requirements in this in-depth guide.

Key Considerations in Choosing a Liquid Filling Machine

Understanding Your Liquid Filling Needs

We discuss the significance of comprehending your unique liquid filling needs in this part. The best filling machine for your company depends on a number of factors, including production volume, container type, and viscosity.

Analyzing Viscosity Levels

It’s essential to comprehend your liquid’s viscosity. For optimum outcomes, pick an instrument that can control the viscosity of the water, as filling treatments differ based on the type of water.

Container Compatibility

Examine the range of containers that your company uses. To provide a flawless and effective procedure, the filling machine must be perfectly aligned with your container types, whether they be bottles, jars, or pouches.

Budgetary Considerations

The financial considerations of purchasing a liquid filling machine are covered in this part, with a focus on the significance of striking a balance between price and quality.

Determining Your Budget

Set a precise spending limit for the liquid filling machine. Assess both the upfront and ongoing expenses for repair and upkeep.

Return on Investment (ROI) Analysis

Analyze the possible return on investment by taking into account elements like improved manufacturing efficiency, less waste, and overall cost savings. This study guarantees a thoughtful choice of investments.

Technology and Automation

This section examines the benefits and possible downsides of technology and automation as they relate to liquid filling machines.

Embracing Technological Advancements

Examine the newest technological features available in liquid filling equipment, including digital monitoring, precise controls, and automatic filling. Evaluate how these developments correspond with your production objectives.

Coupling Machine and Human Input

Although automation has its uses, it must be balanced with input from users. Look for a machine that enables operators to step in when necessary to maintain process flexibility.

Quality Assurance and Compliance

Here, we go over the value of quality control in liquid filling as well as the necessity of selecting a machine that complies with industry standards.

Ensuring Product Quality

To ensure reliable and superior fills, choose a filling machine with features like drip-free nozzles and precise measuring systems.

Compliance with Industry Standards

Verify certificates and adherence to industry standards to steer clear of any possible legal or regulatory problems. Safety and quality criteria should be followed by a dependable liquid filling machine.

What is the procedure for selecting a liquid filling machine?

We offer comprehensive guidance on how to choose a liquid filling machine in this part, so that you can make decisions that are methodical and well-informed.

Step 1: Assessing Liquid Properties

Start by learning everything there is to know about the liquid you plan to fill. Take into account viscosity, temperature sensitivity, and any particular traits that can affect the filling procedure.

Step 2: Identifying Container Specifications

Choose the sizes and kinds of containers that will be used to hold your goods. Aligning filling machines is essential for efficiency as they cater to different container standards.

Step 3: Estimating Production Volume

Analyze your production requirements to ascertain the filling speed and capacity needed. This phase makes sure the machine you’ve chosen can handle the demands of your company.

Step 4: Budget Allocation

Set aside a reasonable amount of money for your liquid filling machine. Think about possible improvements and continuing maintenance in addition to the initial cost.

Step 5: Researching Suppliers

Look into reliable manufacturers and suppliers. For an assessment of the dependability and effectiveness of the liquid filling machines they provide, look for case studies, reviews, and testimonials.

Step 6: Requesting Demos and Samples

Ask prospective vendors for product samples and demos before deciding on a provider. You can evaluate the machine’s functionality and suitability for your particular needs through this hands-on experience.

FAQs about Selecting a Liquid Filling Machine

Q: Are there specific filling machines for different liquid viscosities?

Yes, the viscosities of liquids vary, and specific filling machines are made to effectively manage these variations. Determining the viscosity of your liquid is essential to choosing the appropriate equipment.

Q: How do I ensure my chosen liquid filling machine complies with industry standards?

Verify the manufacturer’s offered compliance papers and certifications. Additionally, make sure the selected machine satisfies all needs by researching industry norms and laws.

Q: Can a liquid filling machine be customized for unique container shapes?

Indeed, a lot of manufacturers provide customization choices to suit odd-shaped containers. To make sure the machine satisfies your manufacturing needs, let the provider know exactly what you need.

Q: What maintenance practices are essential for prolonging the life of a liquid filling machine?

A liquid filling machine’s longevity is dependent on routine maintenance, lubrication, and cleaning. To avoid malfunctions and guarantee dependable operation, according to the manufacturer’s maintenance recommendations,.

Q: Is it advisable to invest in a fully automated liquid filling machine?

The choice is based on your budget and production needs. Automation can be efficient, yet in some cases, manual control is still required. The ideal strategy is frequently to find a balance between automation and manual control.

Q: How can I estimate the ROI of a liquid filling machine investment?

Determine the possible cost reductions from improved manufacturing effectiveness, decreased waste, and other elements. To calculate the return on investment, compare this to the machine’s initial and ongoing costs.

Conclusion

In summary, choosing a liquid filling machine necessitates a calculated strategy that takes into account the qualities of the liquid, the requirements of the container, the available funds, and technical advancements. Businesses can make well-informed decisions that result in effective and economical liquid packaging procedures by adhering to the described approach and keeping the FAQs in mind.