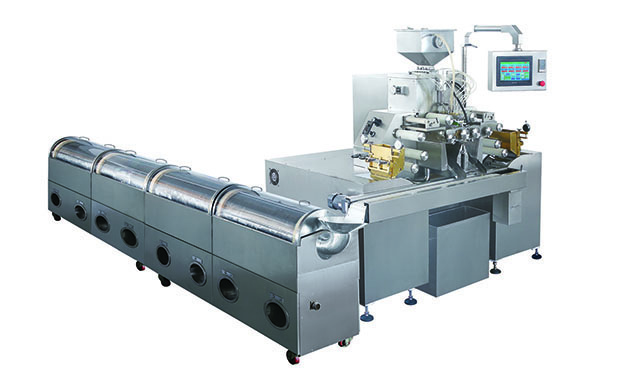

Real World Example Of A Softgel Encapsulation Machine

Time:Jun 30, 2024 Hits:Softgel encapsulation machines are fascinating pieces of technology. These machines are used in many industries, from pharmaceuticals to health supplements. They help make softgel capsules, easy-to-swallow pills that can hold liquids, pastes, or powders.

What is Softgel Encapsulation?

Softgel encapsulation is the process of making soft gelatin capsules. These capsules are soft, smooth, and easy to swallow. They are often used for vitamins, medicines, and dietary supplements. The gelatin shell protects the contents inside and makes them easier to take.

How Does a Softgel Encapsulation Machine Work?

A softgel encapsulation machine has several key parts. It starts with a gelatin melting tank. Here, gelatin is melted and mixed with water and glycerin. This mix forms the soft, flexible shell of the capsule.

Next, the melted gelatin moves to a casting drum. The drum cools the gelatin, forming thin sheets. These sheets are then sent to a rotary die system. This system has two rotating dies that shape and cut the gelatin into the desired capsule size and shape.

Benefits of Using Softgel Encapsulation Machines

Softgel encapsulation machines offer many benefits. They make it easy to produce large numbers of capsules quickly and efficiently. The capsules are uniform in size and shape, which is important for dosage accuracy.

These machines also ensure that the capsules are sealed properly. This helps protect the contents from air and moisture, keeping them fresh and effective for longer periods.

Different Types of Softgel Encapsulation Machines

There are different types of softgel encapsulation machines, each designed for specific needs.

Rotary Die Machines

Rotary die machines are the most common type. They are used for high-volume production and can produce thousands of capsules per hour.

Plate Machines

Plate machines are used for smaller production runs. They are more affordable and easier to operate, making them a good choice for smaller companies.

Automatic Machines

Automatic machines are designed for maximum efficiency. They require minimal human intervention, making them ideal for large-scale production.

Real-World Example: The Pharmaceutical Industry

Imagine a large pharmaceutical company that makes vitamin D supplements. They use a softgel encapsulation machine to produce millions of capsules each day.

Step 1: Preparing the Gelatin

The process starts in the gelatin melting tank. Workers add gelatin, water, and glycerin to the tank. The machine heats and stirs the mixture until it becomes a smooth, thick liquid.

Step 2: Casting the Gelatin Sheets

Next, the melted gelatin flows to the casting drum. Here, it cools and forms two thin sheets. These sheets are then fed into the rotary die system.

Step 3: Preparing the Fill Material

Meanwhile, workers prepare the vitamin D oil in a separate tank. The oil is carefully measured and mixed to ensure the right dosage in each capsule.

Step 4: Encapsulating the Fill Material

As the gelatin sheets move through the rotary die system, the vitamin D oil is pumped into them. The two gelatin sheets come together, trapping the oil inside. The machine seals and cuts each capsule, ensuring they are all the same size and shape.

Step 5: Drying the Capsules

Finally, the capsules are sent to a drying tunnel. Here, they spend several hours drying to remove any extra moisture. Once dry, the capsules are ready for packaging and distribution.

Real-World Example: The Health Supplement Industry

Softgel encapsulation machines are also used in the health supplement industry. Let’s consider a company that makes omega-3 fish oil supplements. They use a similar process but with some differences to handle the fish oil.

Preparing the Gelatin

The company starts by melting the gelatin in a tank. They add water and glycerin to get the right consistency for the capsule shells.

Casting the Gelatin Sheets

The melted gelatin is then sent to the casting drum, where it forms thin sheets. These sheets are fed into the rotary die system.

Preparing the Fish Oil

The fish oil is prepared in a separate tank. Keeping the oil at the right temperature is important to ensure it flows smoothly into the capsules.

Encapsulating the Fish Oil

The gelatin sheets and fish oil come together in the rotary die system. The machine pumps the oil into the gelatin sheets, seals them, and cuts them into capsules.

Drying the Capsules

The fish oil capsules are then sent to a drying tunnel. After drying, they are ready for packaging and shipping to stores.

Choosing the Right Softgel Encapsulation Machine

When choosing a softgel encapsulation machine, companies need to consider several factors.

Production Volume

The first thing to consider is the production volume. Large companies with high demand will need a rotary die machine. Smaller companies might opt for a plate machine.

Capsule Size and Shape

Different machines can produce different sizes and shapes of capsules. Companies need to choose a machine that can produce the capsules they need.

Budget

Budget is another important factor. Rotary die machines are more expensive but offer higher production rates. Plate machines are more affordable but have lower production rates.

Maintenance and Support

Finally, companies should consider the maintenance and support offered by the machine manufacturer. Regular maintenance is essential to keep the machine running smoothly.

Which is the best site online for softgel encapsulation machine?

Looking to buy the best softgel encapsulation machine? Please visit Wenzhou Grand Machinery Technology Co., Ltd. They are the top suppliers in the industry. They offer high-quality machines that are efficient and reliable. Their machines ensure each capsule is perfect every time.

They provide excellent customer service and support. They help you choose the right machine for your needs. Plus, their machines are easy to use and maintain.

If you want the best softgel encapsulation machine, visit Wenzhou Grand Machinery Technology Co., Ltd. They have the expertise and the best products to meet your needs.

Final Words

Softgel encapsulation machines assume an essential part in numerous ventures. They assist with creating uniform, top-notch cases rapidly and productively. These machines are fundamental instruments, from huge drug organizations to little safety supplement organizations.