Introduction:

Softgel encapsulation machine can quantificationally inject the oil, mixing suspesionand pasty mass into the capsule to form all kinds of softgel encapsulation withdifferent size,shape and color.Because of the merits of high speed disintegration,easy to oral, hard to oxygenation,easy to store and take, the softgel encapsulationis welcomed by more and more coustomers. Owing to the high productivity,charging exactly, quality stabilization,high finished product rate, it is favoured bymore and more manufacturers and used in the fields of medicine, health products,cosmetic and paintball and so on .

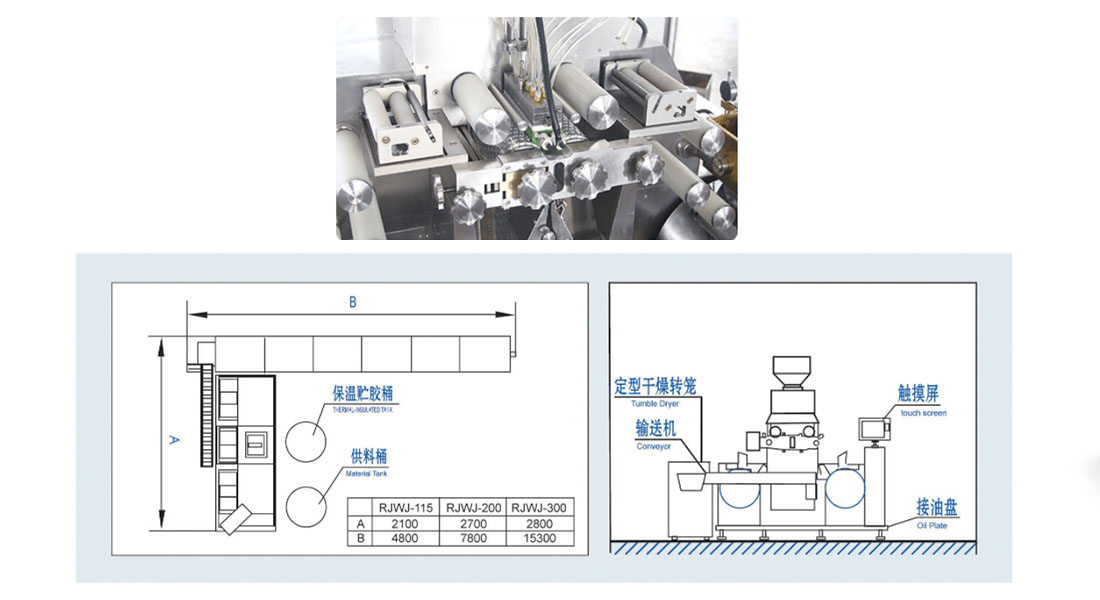

Performance and Characteristics:

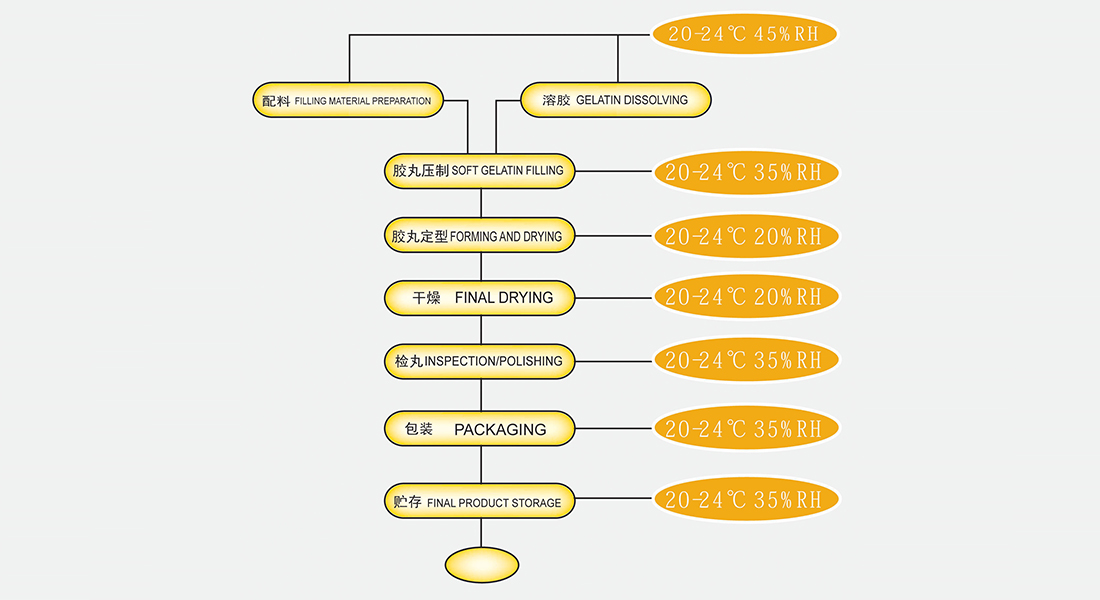

Workflow of Soft Gelatin Capsule:

Main Technical Parameter:

| Model | RJWJ-115 | RJWJ-120 | RJWJ-200 | RJWJ-300 |

| Rotary Speed of Die Roll | 0-5rpm | 0-6rpm | 0-5rpm | 0-5rpm |

| Supplying Volume for Flow Single-pillar |

0.75-1ml | 0.75-1ml | 0.75-2ml | 0.75-2ml |

| Content Uniformity | ±1.5% | ±1.5% | ±2% | ±2% |

| Power for Main Machine | 6.5KW | 7.5KW | 7.5KW | 11.5KW |

| Pillar quantity | 8 | 8 | 12 | 24 |

| Overall Size of Main Machine(L×W×H) | 1600x1000x1650mm | 1600x1000x1650mm | 2100x1100x1800mm | 2200x1275x1900mm |

| Weight of Main Machine | 1160Kg | 1200Kg | 1840Kg | 2189Kg |

Capsule Size & Shape:

Main Technical Parameter:

| Shape | Model | RJWJ-115 | RJWJ-120 | RJWJ-200 | RJWJ-300 | ||||

| Number of Cavities | Capacity of The Medium Speed(Pil/Hour) |

Number of Cavities | Capacity of The Medium Speed(Pill/Hour) |

Number of Cavities | Capacity of The Medium Speed(Pill/Hour) |

Number of Cavities | Capacity of The Medium Speed(Pill/Hour) |

||

| Oval | 4 | 126 | 26460 | 126 | 31680 | 481 | 86580 | 924 | 166320 |

| 8 | 85 | 15300 | 85 | 18360 | 250 | 45000 | 496 | 89280 | |

| 20 | 52 | 9360 | 52 | 11232 | 168 | 30240 | 336 | 60480 | |

| Oblong | 4 | 92 | 16560 | 92 | 19872 | 360 | 64800 | 686 | 123480 |

| 8 | 76 | 13680 | 76 | 16416 | 297 | 53460 | 560 | 100800 | |

| 20 | 45 | 8100 | 45 | 9720 | 162 | 29160 | 288 | 51840 | |

| Round | 8 | 83 | 14940 | 83 | 17920 | 245 | 44100 | 490 | 88200 |

Note : 1minims0.061mg

If you are interested in joining us, please leave your information here, we will contact you as soon as possible.