The round bottle automatic labeling machine uses a non -dry glue roll tube label, the label adopts the cylinder holder method, the automatic bottle is prepared, the bottle is put on the bottle and the label, and the color coding machine can be selected to complete the label production simultaneously to complete the label production.

Product Description:

The round bottle automatic labeling machine uses a non -dry glue roll tube label, the label adopts the cylinder holder method, the automatic bottle is prepared, the bottle is put on the bottle and the label, and the color coding machine can be selected to complete the label production simultaneously to complete the label production. Date printing, this machine is controlled by PLC, tracked simultaneously, and the bid is controlled by the stepper motor to ensure the automated packaging machinery that is synchronized with the bottle speed synchronization. It is a modern mechanical and electrical integrated product with excellent and reliable working performance. The non -dry glue labeling machine has the advantages of cleaning and hygiene, no mold, beautiful, firm, and not falling off by itself, high production efficiency, etc., appearance 304 stainless steel and part of aluminum blacks.

Process:

Enter the bottle: supply the bottle through the conveyor belt or rotation disc.

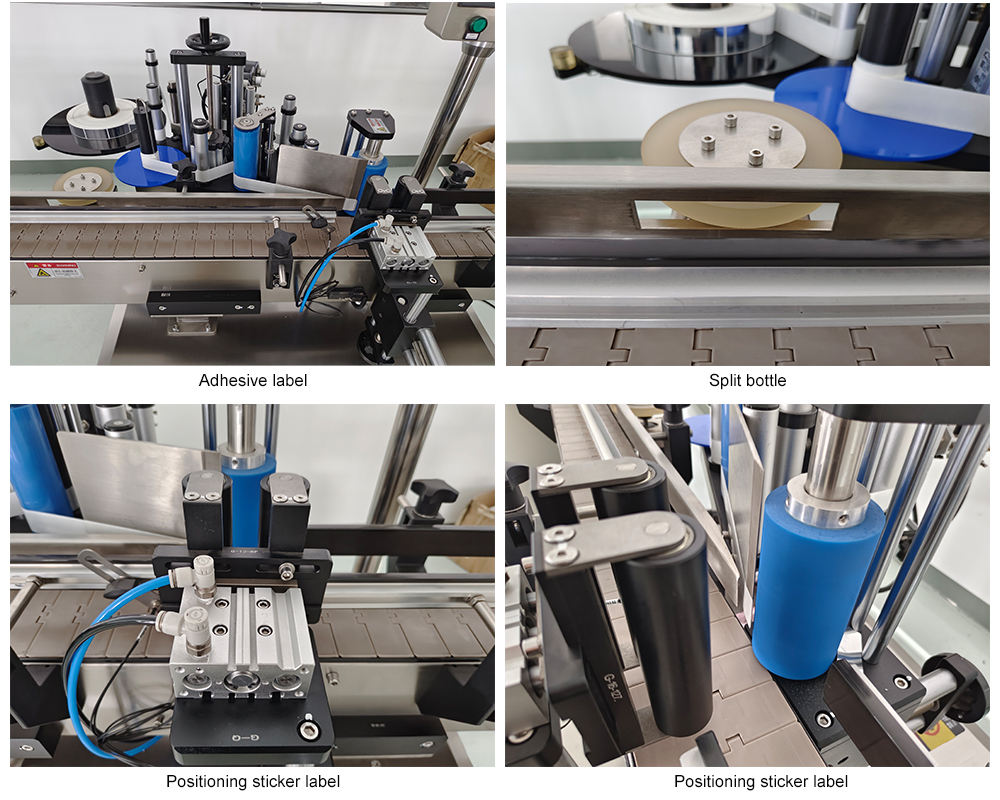

Positioning sensor: The labeling machine is equipped with a sensor for detecting the position of the bottle to ensure that the label is accurate.

Tag supply: Tags are usually provided in the form of roll cylinders. The label is provided to the tag head through automatic rolling or tension control system.

Labeling: Once the bottle is positioned, the label head will accurately attach the label to the surface of the round bottle. Some labeling machines can realize the labels throughout the week, and the label is about to seamlessly stick the entire round bottle surface.

Compact: After labeling, configure the compact device to ensure that the label is fully bonded with the surface of the bottle.

Technical Description:

1)Automatic positioning: Equipped with advanced sensors, the bottle can be automatically detected to accurately set the label position.

2)Adapt to different sizes: The round bottle labeling machine can adapt to a circular bottle of different sizes and shapes, and can adjust the size and position of the label to adapt to different containers.

3)Accurate labeling: They can put the label on the bottle at high speed and high precision to ensure that the location of the label is accurate and avoid waste.

4)Custom labels: The labeling machine supports custom labels, which can print and stick different label content according to the needs of customers.

5)Simple operation: use PLC and touch screen control to simplify the process of operation to reduce the possibility of errors.

6)High -efficiency production: Through automated labeling, it can significantly improve production efficiency and save manpower and time costs.

Main Technical Parameters:

| Power supply | AC 220V/50Hz |

| Power | 1.2KW |

| Applicable product range | D φ30-φ100mm H 30-200mm |

| Applicable label range range | H 15-130mm |

| Label inner diameter | φ76 mm |

| Label outer diameter | φ350 mm |

| Production capacity | 25-75 bottles/min |

| Machine Dimension (L×W×H) | 2000×1100×1400(mm) |

| Machine Weight | 200(KG) |

Component List:

| Name | Place of origin | Brand |

| PLC | Germany | Siemens |

| Touch screen | Germany | Siemens |

| Motor | China | Stepping motor |

| Pneumatic Components | Taiwan | AirTAC |

| Optoelectronics | Germany | Sick |

| Inverter | China | Kokke |

| Obliged light eye | Japan | Matsushita |

Appliscation:

The round bottle label machine is widely used in foods and beverages, medicines, cosmetics, daily necessities and other industries. Whether it is a small -scale production workshop or a large -scale production line, the round bottle labeling machine can help enterprises improve efficiency and label attached quality.

If you are interested in joining us, please leave your information here, we will contact you as soon as possible.