NJYF-300C/600C automatic hard capsule liquid filling and sealing linkage line equipment,is the [domestic first]connecting equipment of hard capsule filling liquid filling and sealing,which is independently developed,designed and produced by our company on the basis of years of capsule filling technology,and owns independent intellectual property rights and a number of technical invention patents.

Overview:

NJYF-300C/600C automatic hard capsule liquid filling and sealing linkage line equipment,is the [domestic first]connecting equipment of hard capsule filling liquid filling and sealing,which is independently developed,designed and produced by our company on the basis of years of capsule filling technology,and owns independent intellectual property rights and a number of technical invention patents. The device can be used to fill hard capsules (solutions,suspensions,microemulsion or hot soluble substances)and seal the binding parts of capsule caps.Make capsules inside the material in the packaging,transportation,and remain the seal in use process,to improve the stability and safety of products,and it can provide a new way of drug delivery,improved the drug problem of many drugs,fill in the pharmaceutical,health care products in the industry at home and abroad blank of hard capsule filling sealing liquid and technology,is also a lot of drug companies,health care products factory for some (highly reactive and difficult to soluble drugs)preparation of product development.

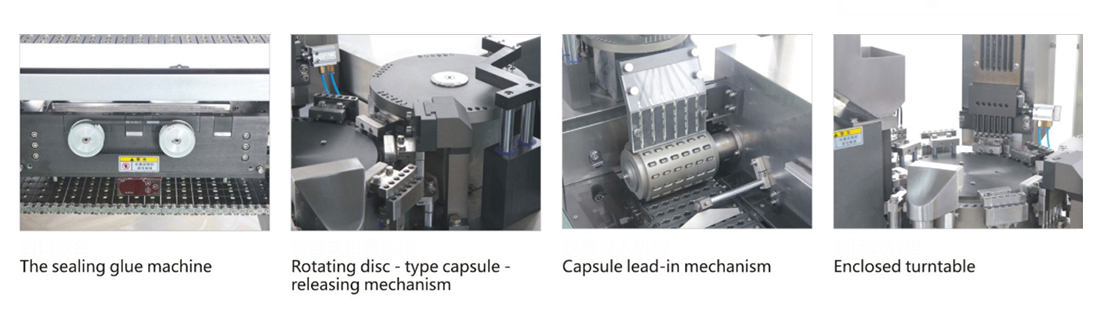

Product performance overview:

Technical Specification:

| Mode | NJYF-300C | NJYF-600C |

| Production | 18000 capsules/hour | 36000 capsules/hour |

| Sealable capsule fillings | Solution, suspended solution, micro -emulsion | Solution, suspended solution, micro -emulsion |

| Die hole number | 6 | 6 |

| Apply the capsule | 00–4# gelatin, plant capsule | 00–4# gelatin, plant capsule |

| Environmental requirements | Room temperature is around 20C, humidity 40%-55% | Room temperature is around 20C, humidity 40%-55% |

| Power supply,voltage | Three-phase 380V/220V, 50Hz | Three-phase 380V/220V, 50Hz |

| The total power | 9KW | 9KW |

| The compressed air | 0.6MPa | 0.6MPa |

| The switchboard weight | 2300KG | 2300KG |

| Installation dimensions | 3800x900x1900mm | 3800x900x1900mm |

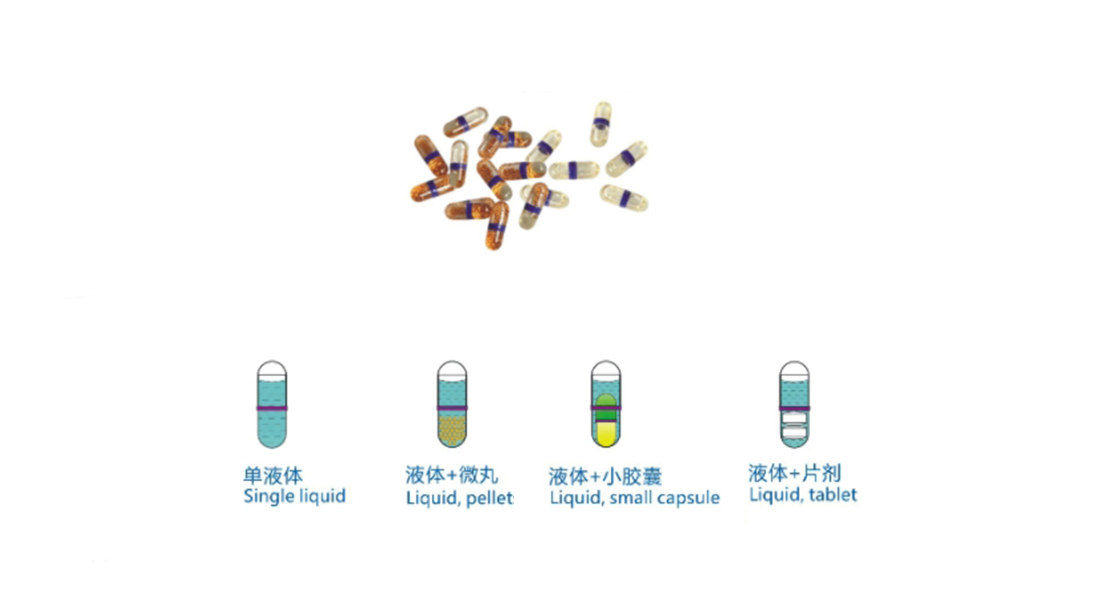

Finished product display:

If you are interested in joining us, please leave your information here, we will contact you as soon as possible.