Using PLC control, packing speed is fast, running smoothly.failure rate is low and energy consumption is low.

Technical characteristics

1. Using PLC control, packing speed is fast, running smoothly.failure rate is low and energy consumption is low.

2. Independent material filling device can effectively avoid backlashand splash of fine powder materials and ensure sealing quality

3. Three-sided sealing and four-sided sealing are optional, makingbags flat and beautiful in appearance.

4. Different filling mechanisms can realize different packaging ofpowder, liquid, granule and sauce.

technicalparameters

| Machine model | HFFS | horizontal bag making, filling and sealing | ||

| Technical characteristics | Bag making way | Roll film bag | ||

| Bag delivery | Intermittent type | |||

| Manufacturing | rack | stainless steel exterior, internal carbon steel surface spray frame | ||

| Internal parts | Carbon Steel Blackening Treatment | |||

| External parts | Anodizing treatment of stainless steel and aluminium alloy | |||

| Roll film size | diameter | 500mm | ||

| Film width | 700mm | |||

| Core diameter | 76mm | |||

| blanking station | 2station | |||

| Machine size | L x W x H | 6600mmx1100mmx2800mm (the height includes the piggy bank) | ||

| Machine weight | 3000Kg | |||

| Bag size | L x W x H | Minimum size (mm) | Maximum dimensions (mm) | |

| FLT-1 | 60×100 | 180•250 | ||

| STU-1 | 60x100x20 | 180x250x90 | ||

| STU-2 | 60*60•100•20 | 100x100x2500x60 | ||

| Production speed and volume | 3、 4-side sealed flat bag Self-supporting bag |

Maximum speed (packets/min) | Maximum volume (ml) | |

| FLT-1 | 60 | 600 | ||

| FLT-2 | 120 | 100 | ||

| STU-1 | 60 | 1000 | ||

| STU-2 | 80 | 300 | ||

| Power consumption | Electric | 8kw | ||

| 120 L/min, 0.6 Mpa | ||||

| Power supply voltage | Compressed airI | 200V-415V, 50-60Hz (or customized according to customer requirements) | ||

| Noise | ≤80dB | |||

| Security standards | Bacrylic protective door | |||

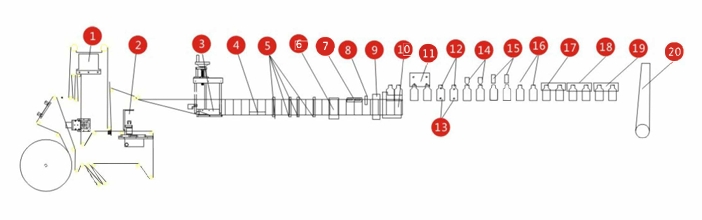

Process Flow Chart

Process Sample

If you are interested in joining us, please leave your information here, we will contact you as soon as possible.