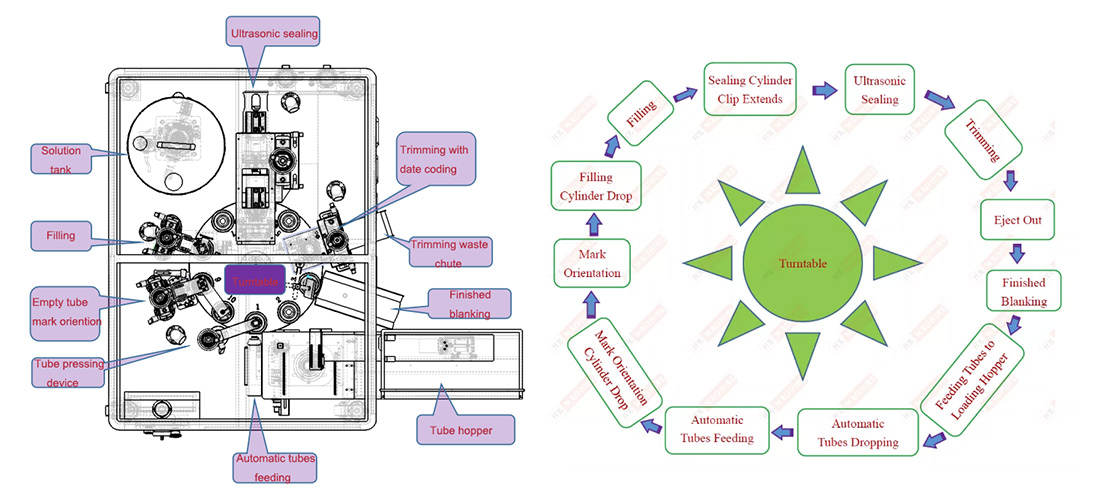

This machine automatically completes a series of actions such as tube feeding, mark orientation, filling, sealing, trimming, and finish product ejecting out. It is fully automatic, saving labor and reducing production costs;

Floorplan/Process Flow

Performance and Feature:

This machine automatically completes a series of actions such as tube feeding, mark orientation, filling, sealing, trimming, and finish product ejecting out. It is fully automatic, saving labor and reducing production costs;

Equipped with safety devices and overload protection;

Precise positioning of the ten-station divider;

Using ultrasonic technology to seal, the sealing effect is firm and lasting; the lines at the seal are clear and not deformed;

Independent research and development of digital ultrasonic automatic frequency tracking electric box, no need to manually adjust the frequency, increase the power automatic compensation function, and will not cause the machine power to drop due to long use time. The power can be adjusted freely according to the material and size of the hose, the output is stable, the failure rate is extremely low, and the service life is longer than that of the ordinary electric box;

Adopt PLC touch screen control, configure fault alarm system, fault information is displayed on the touch screen, which is clear at a glance, and can quickly locate and solve problems;

The whole machine is made of 304 stainless steel, which is resistant to acid and alkali and corrosion;

This machine is equipped with an automatic identification system, no tube, no filling, no sealing, reducing the loss rate of the machine and mold;

Adopt anti-drip filling head;

Main Technical Parameter:

| Model | HX-009S | Frequency | 20KHz |

| Power | 2600W | Power Supply | AC220V 1PH 50/60hz |

| Filling Volume | A:10-120ml/B:25-250ml | Filling Accuracy | ±1% |

| Productivity | 10-13pcs/min | Radius of Sealing | 25-50mm |

| Height of Sealing | 50-250mm | Air Pressure | 0.6MPa |

| Dimension | L1830*W1400*H1780 | Weight | 530Kgs |

Main Parts Details:

| Main part list: | |

| Ultrasonic system | Automatic frequency tracing |

| Benchmarking electric eye | Panasonic, Japan |

| PLC | Mitsubishi, Japan |

| electric relay | Omron, Japan |

| Touch Panel | WEINVIEW,China Taiwan |

| Inductive switch | SICK, Germany |

| Air cylinder | AirTAC,China Taiwan |

| Solenoid valve | AirTAC,China Taiwan |

| Motor | zhongdamotor CN |

| Partitioner | JOUDER,China Taiwan |

| Frequency converter | DELTA,China Taiwan |

| Stepper motor | Leadshine,CN |

If you are interested in joining us, please leave your information here, we will contact you as soon as possible.