The machine is controlled by the PC button or the PLC programmable program control, which can automatically complete the processes such as forming, feeding, heat sealing, indentation, and tailoring.

Product Introduction:

The machine is controlled by the PC button or the PLC programmable program control, which can automatically complete the processes such as forming, feeding, heat sealing, indentation, and tailoring. The whole machine strictly designed in accordance with the requirements of the pharmaceutical industry’s “GMP” specification. The overall function is advanced, the operation is simple, and the output is high. It is an ideal packaging equipment for pharmaceutical companies, health products and food.

The finished product is widely used, and it can realize a variety of packaging methods such as aluminum plastic, paper plastic, aluminum and aluminum.

Technical Description:

1. The whole machine structure is simple:

Optimize the transmission structure on the basis of the original basis, the forming range is wider, the transmission is more accurate, and the noise is smaller.

2. General platform:

The product work surface and the bottom transmission are separated to avoid cross -pollution and easy to clean.

3. Fast -installed mold:

The design of each station has a positioning benchmark to quickly achieve mold replacement. Each adjustment component has a scaled scale, which is accurately adjusted according to product requirements.

4. Automatic waste collecting mechanism:

Automatically collect waste, realize machine automation, standardized production, and save labor;

5. Manual inheritance axis:

It is more convenient and fast to disassemble.

6. Customized configuration:

Cursor to version, indentation mechanism, secondary molding.

Technical Parameters:

| Model | DPP-100 |

| Number of routing (production capacity) | 10-35 times/minute (number of X plates) |

| Maximum mold area and depth | 80*105*26 (mm) |

| Standard itinerary | 35-85mm (can be designed according to customer requirements) |

| Standard section | 80*57mm (can be designed according to customer requirements) |

| Compressed air | 0.6-0.8MPa ≥0.3m³/min |

| rated power | 2.4kw 220/380v 50Hz, |

| PVC hard film specification | 0.15-0.5*120 (mm) |

| PTP aluminum foil specification | 0.02-0.035*120 (mm) |

| Dialysis paper specification | 50-100g*120 (mm) |

| Mold cooling | Tap water or circulating water |

| Dimensions | 1938*592*1199 (mm) |

| weight | 450 kg (kg) |

| Noise indicator | <75dba |

Machine size:

Machine component:

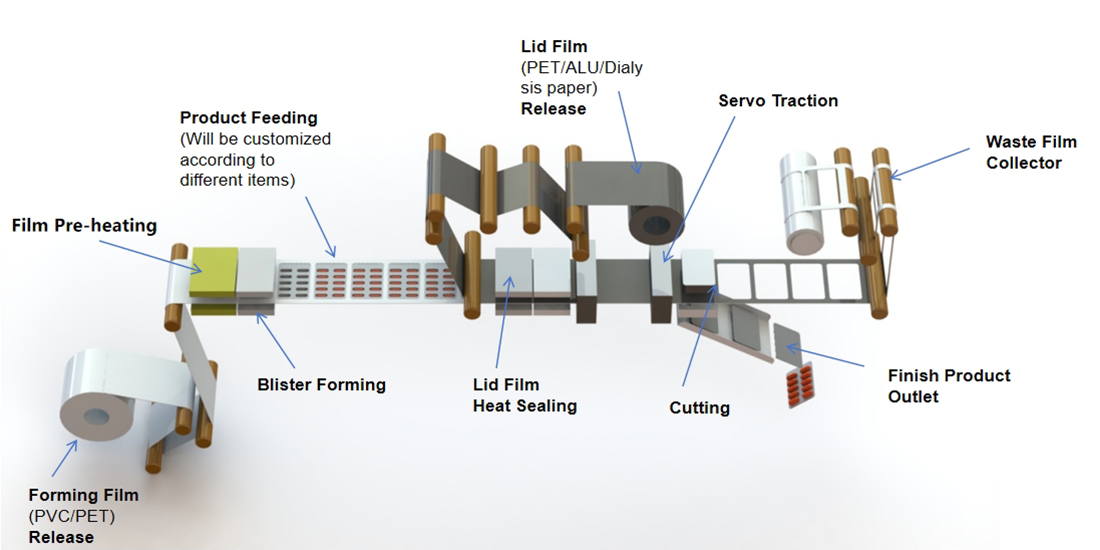

Flowchart:

Finished product display:

If you are interested in joining us, please leave your information here, we will contact you as soon as possible.