What Is A Wrapper Sealing Machine

Time:Apr 27, 2024 Hits:What is a wrapper sealing machine? A wrapper sealing machine is a fantastic tool that helps in packaging. Imagine you have a candy bar. This machine wraps it up neatly in a film, creating a pouch or bag. It’s like a little gift wrapper for products!

Here’s how it works. The machine has a roll of film. It feeds this film continuously, while products move into the film. Then, it wraps the film around each product and seals it. It’s like wrapping a present and putting tape on it. But this machine does it super fast, even up to 200 packages per minute!

This machine is very precise and can make packages of the same quality and shape. It’s perfect for many products, from snacks to medicines. So, it not only makes the product look good but also keeps it safe and increases its shelf life.

Advantages of wrapper sealing machines

In the realm of packaging, wrapper sealing machines are a huge advantage. They bring a large group of advantages that make them a fundamental piece of any packaging cycle. How about we dig into the benefits they offer?

First, these machines altogether increment proficiency. They mechanize the packaging system, empowering fast and exact wrapping of items. This speed and precision beat manual techniques, prompting a smoother work process.

Also, wrapper sealing machines give upgraded item assurance. The tight seal they make around the item prepares for outside factors like residue, dampness, and harm during travel. This guarantees that the item arrives at the client in the most ideal condition.

Thirdly, the utilization of these machines prompts a significant decrease in labor costs. Since they computerize the packaging system, fewer unskilled workers are required. This reduces work expenses, making the general interaction more practical.

Lastly, these machines offer flexibility. They can bundle many items, from food things to hardware, effortlessly. This flexibility makes them an important resource in different enterprises.

Types of wrapper sealing machines

Wrapper sealing machines come in different kinds, each intended to take care of explicit packaging needs. We should investigate three principal types: Horizontal, Vertical, and Rotary wrapper sealing machines.

Horizontal Wrapper Sealing Machines

These machines are great for items that are long and challenging to shift. They wrap the item on a level plane, guaranteeing a tight and secure seal. This sort of machine is normally utilized in businesses managing long items like lines, poles, and timber.

Vertical Wrapper Sealing Machines

As the name recommends, these machines wrap the item in an upward direction. They are ideally suited for tall, upstanding things that are hard to lay level. These machines are much of the time found in ventures packaging things like jugs, containers, and jars.

Rotary Wrapper Sealing Machines

These machines turn the item while wrapping it, guaranteeing an even and secure seal all over. They are flexible and can deal with an extensive variety of item shapes and sizes. You’ll frequently find these machines in enterprises managing different items.

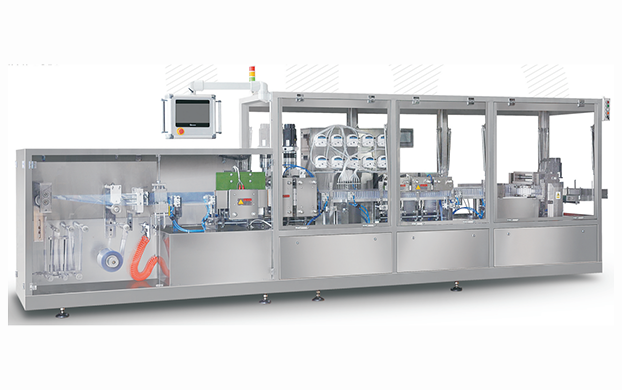

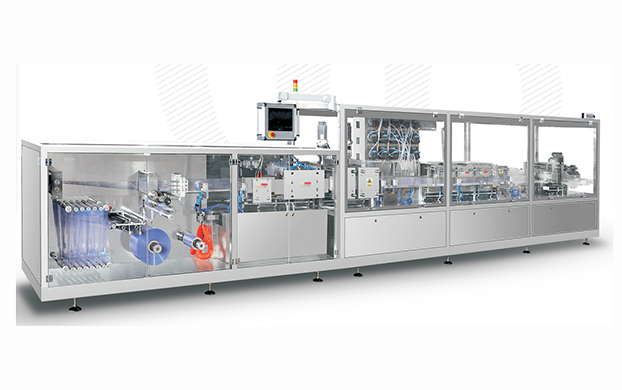

Components of a wrapper sealing machine

A wrapper sealing machine is a wonder of present-day designing that assumes a significant part in packaging ventures. How about we plunge into the key parts that make this machine work?

The belt is the core of the machine. It ships the item starting with one station and then onto the next, guaranteeing a smooth progression of tasks. The transport line is intended to deal with results of different sizes and shapes, making it flexible and proficient.

The 2nd part is the film roll holder. This part holds the film roll, which is utilized to wrap the item. The film roll holder is flexible, taking into account the various sizes of film rolls to be utilized. It guarantees the film is taken care of in the machine at a consistent rate, keeping up with consistency in the wrapping system.

The third part is the fixing instrument. This is where the sorcery occurs. The fixing system utilizes intensity to seal the film around the item, making a tight and secure wrap. It’s intended to work rapidly and productively, fixing many items in 60 minutes.

Following the fixing instrument, we have the cutting system. When the item is fixed, the cutting instrument manages the overabundance film, giving the bundle a slick and clean appearance. The cutting system is sharp and exact, guaranteeing a well-put-together without fail.

Ultimately, the control board is the mind of the machine. It permits administrators to control the speed of the transport line, the temperature of the fixing system, and different settings. The control board makes the machine simple to work and change as indicated by the necessities of the item.

Applications of wrapper sealing machines

Wrapper sealing machines are flexible apparatuses that track down applications in different ventures. We should investigate a portion of these applications.

Food packaging

Food packaging machines are essential. They assist with guarding food new and from toxins. Whether it’s fixing packs of chips or wrapping frozen pizzas, these machines guarantee that our food contacts us in wonderful condition. They likewise assist in lessening food squandering by expanding the timeframe of realistic usability of items.

Pharmaceutical packaging

Here, the job of wrapper sealing machines is basic. They guarantee that drugs are safely fixed, shielding them from dampness and defilement. This is fundamental as it keeps up with the viability of the meds, guaranteeing that they give the expected restorative impact.

Cosmetic packaging

Thirdly, in the realm of beauty care products, these machines play a key part. They assist with packaging different corrective items, from lipsticks to creams. The solid fixing guarantees that the items don’t release or get tainted, keeping up with their quality and viability.

Industrial packaging

Ultimately, wrapper sealing machines track down broad use in Industrial packaging. They assist with packaging different modern merchandise, from spare parts to large equipment. The powerful fixing guarantees that the items are shielded from harm during transportation and capacity.