What’s The Best Kind Of Filling Machine

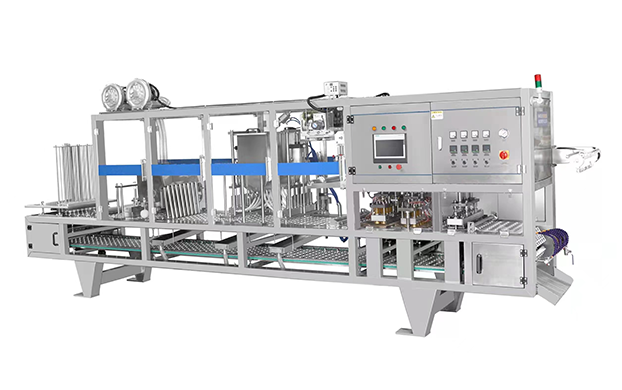

Time:Apr 7, 2024 Hits:Picking the right filling machine is critical to doing great in the food bundling business. The right machine makes work quicker, keeps the item great, and makes things more effective. What’s The Best Kind Of Filling Machine?

To start with, ponder what item you’re pressing. Various items need various machines. They rely heavily on how thick the item is, its surface, and the way that reliable it is. For instance, machines for fluid items like juices are unique to those for thick items like sauces or glues.

To start with, ponder what item you’re pressing. Various items need various machines. They rely heavily on how thick the item is, its surface, and the way that reliable it is. For instance, machines for fluid items like juices are unique to those for thick items like sauces or glues.

Then, take a gander at the amount you produce. Pick a machine that can deal with your ongoing necessities yet additionally takes into consideration development. A machine that is too small can create setbacks. A machine that is too huge can be exorbitant and not effective.

Then, centers around unwavering quality and simple upkeep. A solid machine implies less free time and lower upkeep costs. This keeps your creation line moving without a hitch. Go for machines that are not difficult to utilize and keep up with.

At long last, remember your spending plan. It’s essential to put resources into a decent filling machine, yet it ought to likewise fit reasonably affordable for you. Take a gander at various choices and consider their highlights, how well they work, and if they’re worth the expense.

Best Kind Of Filling Machine and What They Do

Picking the right filling machine is vital in the food bundling business. There are many sorts, each with extraordinary elements. We should take a gander at these machines and what they do:

-

Overflow Filling Machines

These machines are perfect for filling fluids, particularly ones that froth or sprinkle. They fill holders to a specific level, it is something similar to ensure everyone. They are frequently utilized for things like beverages, oils, and sauces.

Key Elements:

- They control the filling level exactly.

- They function admirably with frothy or thick fluids.

- They squander next to no item as a result of their plan.

-

Piston Filling Machines

These machines are adaptable and effective. They can deal with the results of numerous thicknesses. They utilize a cylinder to precisely place items into holders. They are frequently utilized for things like creams, salves, and glues.

Key Elements:

- They fill by volume precisely.

- You can change the fill volume and speed.

- They function admirably with thick or stout items.

-

Gravity Filling Machines

These machines use gravity to fill holders. They function admirably with fluids that stream unreservedly like water, squeeze, and wine. They are not difficult to utilize and keep up with, which makes them famous for little to medium-sized creations.

Key Highlights:

- They are a financially savvy method for filling fluids.

- They do have not many complex components, so they need less support.

- You can change the filling speeds for various holder sizes.

-

Vacuum Filling Machines

Vacuum Filling Machines

These machines fill holders with fluids and eliminate air from the item. This assists the item with enduring longer by lessening oxidation. They are frequently utilized for things like sauces, soups, and toppings.

Key Elements:

- They eliminate air to further develop item quality.

- They function admirably with both hot and cold fill applications.

- They assist transitory items with enduring longer.

-

Net Gauge Filling Machines

These machines measure items by weight to fill precisely, regardless of how thick or thick the item is. They are frequently utilized for things like grains, nuts, and powders. These machines are incredible when precision is vital.

Key Elements:

- They fill by weight precisely.

- They work with many kinds of items.

- They offer next to no items, making them productive.

-

Auger Filling Machines

These machines utilize a turning screw to place powdered or granular items into holders. They are frequently utilized for things like flavours, flour, and drugs. They control the fill volume unequivocally and function admirably with both free-streaming and sans-non-streaming items.

Key Highlights:

- They fill by volume precisely for powders and granules.

- You can change the fill volume and speed.

- They are not difficult to clean and keep up with, which is great for cleanliness.

Choosing a Filling Machine: Key Factors

Picking the right filling machine for your food-pressing necessities is significant. It can influence your business’ effectiveness and benefits. Here are a few elements to contemplate:

Sort of Item

Contemplate the item you will fill. Take a gander at its highlights like thickness, surface, and molecule content. Various machines work best with explicit items. Along these lines, pick one that suits your item.

Creation Volume and Speed

Take a look at your creation volume and filling speed needs. Pick a machine that can stay aware of your requests. It shouldn’t dial back your cycle. Balance speed and precision for proficient work.

Exactness and Accuracy

Precision matters a great deal in filling machines. This is particularly valid for items sold by weight or volume. Pick a machine that controls fill levels well. This can diminish waste and keep clusters predictable.

Convenience and Support

Go for a machine that is not difficult to utilize and keep up with. A machine with straightforward controls and less arrangement can make your cycle smoother. It can likewise chop down preparation time. Likewise, pick a machine that is not difficult to clean and keeps everything looking great.

Adaptability and Flexibility

Pick a machine that can adjust to changes underway and item types. Search for highlights like movable fill volumes, swappable parts, and an extensive variety of compartment sizes and types.

Cost and Financial Plan

Contemplate your financial plan and the complete expense of claiming the machine. It’s vital to put resources into a decent machine, yet additionally look out for costs like upkeep, parts, and consumables.

Industry Rules and Consistency

Ensure your machine observes industry guidelines and norms for sanitation and bundling. Check for accreditations and consistency reports to ensure the machine meets all necessities.

Provider Notoriety and Backing

Pick a provider with a decent standing. They ought to give top-notch machines and extraordinary client service. See things like guarantee, specialized help, and accessibility of extra parts.

Finally, picking the right filling machine needs a cautious idea. Consider factors like item type, creation volume, exactness, convenience, adaptability, cost, consistency, and provider notoriety. By taking into account these variables and doing a great examination, you can settle on a brilliant decision for your business’ progress in the food bundling industry.