What Is Liquid Capsule Filling Machine

Time:Mar 24, 2024 Hits:Liquid capsule filling machines are very important in the world of medicine and supplements. They help make the production process better and more accurate. This helps improve the quality and availability of important medicines and supplements. These machines make the filling process automatic. This makes operations smoother, reduces mistakes, and increases productivity. Both small startups and big medicine makers find these machines very important. They help bring new ideas to life and meet the increasing needs of customers all over the world.

What is Liquid Capsule Filling Machine?

A liquid capsule filling machine is a tool used to make medicines or supplements. It fills capsules with liquid automatically. This makes the process accurate and efficient and reduces mistakes. The liquid goes into the machine’s tank, and then it goes into each capsule. This is very important for making sure the dosage is correct. These machines come in different sizes and can make different amounts of capsules. They are easy to use, with simple controls.

Benefits of Liquid Capsule Filling Machines

If you take medicines or supplements, you know it can be hard to work quickly and accurately. Liquid capsule-filling machines can help with this.

- Efficiency: These machines can make a lot of capsules in a short time. This means you can meet demands quickly without lowering quality.

- Accuracy: With these machines, you can be sure that each capsule has the right amount of liquid. This means there’s no risk of giving too much or too little. This makes the product work well and keeps customers safe and happy.

- Versatility: These machines can work with many types of liquids, like oils or solutions. This means you can meet many market demands without needing many machines.

- Cost-Effectiveness: These machines fill capsules automatically, which cuts down on labor costs. They also reduce the chance of mistakes, saving you time and resources.

Types of Liquid Capsule Filling Machines

If you make medicines or supplements, you need to know about different types of liquid capsule-filling machines. There are three main types: manual, semi-automatic, and automatic.

Manual Machine

A manual machine is simple but important, especially for small businesses. You fill each capsule by hand. This takes a lot of work but is good for startups because it’s cheap. It’s not the fastest, but it’s good for making small amounts with high accuracy.

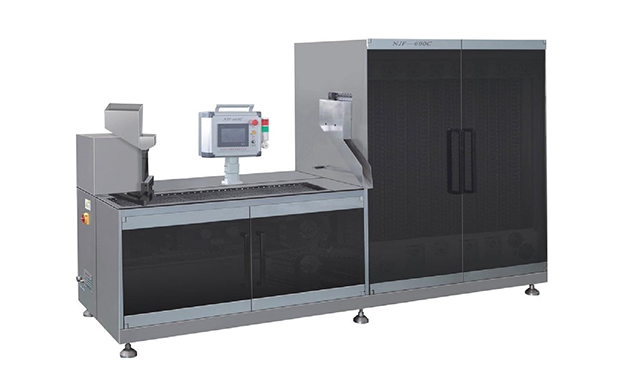

Semi-Automatic Machine

A semi-automatic machine is a step up. You put empty capsules into the machine, and it fills them with liquid. This makes the process more efficient. This type is good for medium-sized businesses that want to work faster but are not fully automated.

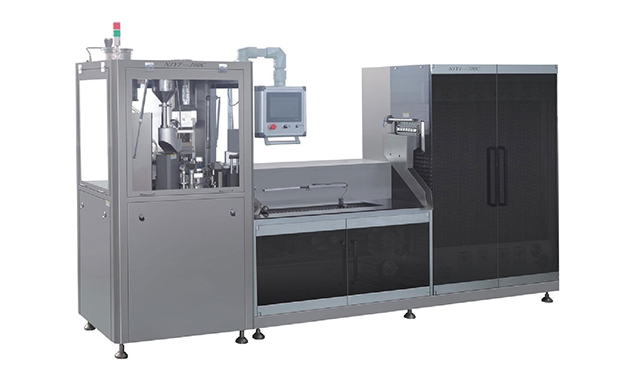

Automatic Machine

An automatic machine is the most efficient. It does everything from loading capsules to filling and sealing them. You don’t need to do much. This is great for big businesses. It makes sure the quality is consistent and you can make a lot of capsules. But it costs more at first.

Changing Types and Things to Consider

You may switch from one kind of equipment to another as your firm grows. When selecting a machine, take into account your income, spending limit, and future goals. Additionally, bear in mind that keeping your equipment operating properly depends on regular maintenance and manufacturer assistance.

Considerations for Choosing a Liquid Capsule Filling Machine

The pharmaceutical and supplement industries depend on selecting the right liquid capsule filling machine to guarantee efficient operations and high-quality products. Let’s examine the key elements to think about:

The pharmaceutical and supplement industries depend on selecting the right liquid capsule filling machine to guarantee efficient operations and high-quality products. Let’s examine the key elements to think about:

Ability to Produce

Evaluate your needs for production first. Calculate the number of capsules you must fill in a set time.

To prevent bottlenecks or underutilization of your equipment, select one that is in line with your production capacity.

Types of Capsules Compatible

Take into account the sizes and varieties of capsules that your company uses.

Make sure the machine you choose works with the particular capsules you intend to use—vegetarian, gelatin, or other—if that is the case.

Precision and Accuracy

In the pharmaceutical business, maintaining exact dose control is crucial.

To guarantee accurate and dependable dosage for every capsule, look for a piece of filling equipment with excellent levels of precision.

Ease of Operation and Maintenance

Choose a machine that requires little training from its operators and is easy to use.

To prevent downtime and expensive repairs, take into account the machine’s maintenance requirements as well.

Select a model with easily replaceable parts and simple upkeep instructions.

Cost-Effectiveness

Determine the machine’s total cost-effectiveness by taking into account the initial outlay as well as long-term savings.

Last Words

Making supplements and medications requires the use of liquid capsule-filling machines. Both manufacturing quality and dose accuracy get better by them. They facilitate the delivery of essential medications and nutrients to those in need. These devices become better as technology advances. To satisfy consumer demands, they adjust. They are dependable, precise, and adaptable. They support scientific research, companies in expansion, and patients. We cannot undervalue the significance of these devices. To remain ahead of the curve and advance healthcare, use them.